Galvanized Roller Shutter Door

-

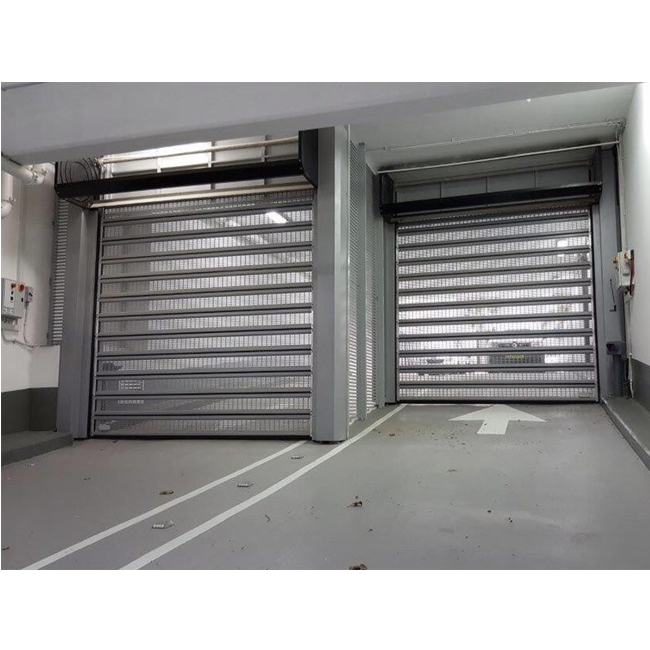

Galvanized Roller Shutter Garage Door

1. Toughest coating. A galvanized coating has a unique metallurgical structure which gives outstanding resistance to mechanical damage in transport, erection and service.

Email Details

2. A full protective coating can be applied in minutes; The galvanizing process is not dependent on weather conditions

3. Lowest first cost. Galvanizing is lower in first cost than many other commonly specified protective coatings for steel. (The application cost of labour intensive coatings such as painting has risen far more than the cost of factory operations such as galvanizing.) -

Top Quality Galvanized Steel Metal Roller Shutter Door

1. Reliability. Galvanizing is carried out to Australian / New Zealand Standard 4680, and standard, minimum coating thicknesses are applied. Coating life and performance are reliable and predictable.

Email Details

2. Toughest coating. A galvanized coating has a unique metallurgical structure which gives outstanding resistance to mechanical damage in transport, erection and service.

3. Automatic protection for damaged areas. Galvanized coatings corrode preferentially to steel, providing cathodic or sacrificial protection to small areas of steel exposed through damage. Unlike organic coatings, small damaged areas need no touch up. -

Hot

Theftproof Strongly Guarded Galvanized Roller Shutter Door

1. Toughest coating. A galvanized coating has a unique metallurgical structure which gives outstanding resistance to mechanical damage in transport, erection and service.

2. Automatic protection for damaged areas. Galvanized coatings corrode preferentially to steel, providing cathodic or sacrificial protection to small areas of steel exposed through damage. Unlike organic coatings, small damaged areas need no touch up.

3. Less maintenance/Lowest long term cost. Even in cases where the initial cost of galvanizing is higher than alternative coatings, galvanizing is almost invariably cheapest in the long term (because it lasts longer and needs less maintenance). And, maintenance causes problems and adds to costs when structures are located in remote areas, and when plant shutdown or disruption to production is involved.Theftproof Galvanized Rolling Shutter Door Galvanized Roller Shutter Door Strongly Guarded Galvanized Roller Shutter DoorEmail Details -

Hot

Commercial Galvanized Micro Perforated Color Roller Shutter Door

1.Complete protection. Every part of a galvanized article is protected, even recesses, sharp corners and inaccessible areas. No coating applied to a structure or fabrication after completion can provide the same protection.

2. Less maintenance/Lowest long term cost. Even in cases where the initial cost of galvanizing is higher than alternative coatings, galvanizing is almost invariably cheapest in the long term (because it lasts longer and needs less maintenance). And, maintenance causes problems and adds to costs when structures are located in remote areas, and when plant shutdown or disruption to production is involved.

3. A full protective coating can be applied in minutes; The galvanizing process is not dependent on weather conditionsGalvanized Micro Perforatedroller Rolling shutter door Galvanized Color Roll Up Shutter Door Commercial Galvanized Rolling Shutter DoorEmail Details -

Automatic Galvanized Roller Shutter Door Components

1. Faster erection time. As galvanized steel members are received they are ready for use. No time is lost on-site in surface preparation, painting and inspection. When assembly of the structure is complete, it is immediately ready for use, or for the next construction stage.

2. Lowest first cost. Galvanizing is lower in first cost than many other commonly specified protective coatings for steel. (The application cost of labour intensive coatings such as painting has risen far more than the cost of factory operations such as galvanizing.)

3. Long life. The life expectancy of galvanized coatings on typical structural members is far in excess of 50 years in most rural environments, and 20 to 25 years plus, even in severe urban and coastal exposure.Galvanized Roller Shutter Door Components Automatic Galvanized Rolling Shutter Door Galvanized Roller Shutter DoorEmail Details -

Motorized Operation MS Roller Shutter Door

1. Automatic protection for damaged areas. Galvanized coatings corrode preferentially to steel, providing cathodic or sacrificial protection to small areas of steel exposed through damage. Unlike organic coatings, small damaged areas need no touch up.

Email Details

2. Lowest first cost. Galvanizing is lower in first cost than many other commonly specified protective coatings for steel. (The application cost of labour intensive coatings such as painting has risen far more than the cost of factory operations such as galvanizing.)

3. A full protective coating can be applied in minutes; The galvanizing process is not dependent on weather conditions -

Automatic Remote Control Galvanized Iron Roller Shutter Door

1. Lowest first cost. Galvanizing is lower in first cost than many other commonly specified protective coatings for steel. (The application cost of labour intensive coatings such as painting has risen far more than the cost of factory operations such as galvanizing.)

2. Complete protection. Every part of a galvanized article is protected, even recesses, sharp corners and inaccessible areas. No coating applied to a structure or fabrication after completion can provide the same protection.

3. Toughest coating. A galvanized coating has a unique metallurgical structure which gives outstanding resistance to mechanical damage in transport, erection and service.Galvanized Iron Punched Roll Up Door Automatic Punched Rolling Shutter Door Remote Control Roll Up Shutter DoorEmail Details -

Automatic Galvanized Roller Garage Door

1. Long life. The life expectancy of galvanized coatings on typical structural members is far in excess of 50 years in most rural environments, and 20 to 25 years plus, even in severe urban and coastal exposure.

Email Details

2. Complete protection. Every part of a galvanized article is protected, even recesses, sharp corners and inaccessible areas. No coating applied to a structure or fabrication after completion can provide the same protection.

3. Lowest first cost. Galvanizing is lower in first cost than many other commonly specified protective coatings for steel. (The application cost of labour intensive coatings such as painting has risen far more than the cost of factory operations such as galvanizing.) -

Home Security Interior Metal Galvanized Rolling Shutter Door

1. Faster erection time. As galvanized steel members are received they are ready for use. No time is lost on-site in surface preparation, painting and inspection. When assembly of the structure is complete, it is immediately ready for use, or for the next construction stage.

2. Lowest first cost. Galvanizing is lower in first cost than many other commonly specified protective coatings for steel. (The application cost of labour intensive coatings such as painting has risen far more than the cost of factory operations such as galvanizing.)

3. Complete protection. Every part of a galvanized article is protected, even recesses, sharp corners and inaccessible areas. No coating applied to a structure or fabrication after completion can provide the same protection.Metal Galvanized Rolling Shutter Door Interior Galvanized Roller Shutter Door Home Security Galvanized Roll Up Shutter DoorEmail Details